In today’s industrial landscape, sustainability has become a key priority for manufacturers across all sectors, including logistics and material handling. Truck loading conveyors are vital components in warehouse operations, enabling efficient movement of goods and reducing manual labor. However, the environmental impact of manufacturing these systems has drawn attention from both regulators and businesses aiming to adopt greener practices. Sustainable manufacturing practices among truck loading conveyor manufacturers are reshaping the industry, ensuring that efficiency and productivity go hand in hand with environmental responsibility.

Sustainability in conveyor manufacturing involves reducing resource consumption, minimizing waste, and lowering energy usage during production. Reputable Truck Loading Conveyor Manufacturers are increasingly adopting environmentally friendly approaches, including the use of recycled materials, energy-efficient production processes, and eco-friendly designs. These practices not only reduce the carbon footprint of manufacturing operations but also align with the growing global demand for sustainable supply chain solutions.

Use of Recycled and Eco-Friendly Materials

One of the primary steps manufacturers take toward sustainability is the use of recycled and eco-friendly materials. Components such as steel frames, aluminum rollers, and conveyor belts can often be produced from recycled sources without compromising durability or performance.

In addition, some manufacturers are incorporating biodegradable or recyclable plastics for non-structural components, reducing the environmental impact at the end of the conveyor’s lifecycle. Using eco-friendly materials helps conserve natural resources and reduces waste, contributing to the overall sustainability of the product.

Energy-Efficient Manufacturing Processes

Energy consumption is a significant factor in manufacturing environmental impact. Leading truck loading conveyor manufacturers implement energy-efficient practices in their production processes, including optimized machinery operation, automated control systems, and energy recovery solutions.

For example, advanced fabrication techniques minimize electricity and fuel consumption during metal cutting, welding, and assembly processes. Additionally, some manufacturers use renewable energy sources such as solar or wind power in their factories to further reduce greenhouse gas emissions.

Minimizing Waste and Recycling Programs

Sustainable manufacturing also focuses on minimizing waste generated during production. Excess materials, scrap metal, and defective parts can contribute significantly to landfill waste if not managed properly. Manufacturers implement recycling programs that recover and repurpose these materials, ensuring that little is wasted.

Waste reduction strategies also extend to packaging. Many manufacturers now use biodegradable, reusable, or recyclable packaging materials to ship conveyors and components, reducing the environmental footprint of transportation and logistics.

Water Conservation and Pollution Control

Some truck loading conveyor manufacturers employ water conservation practices and pollution control measures during manufacturing. Processes such as cooling, cleaning, and finishing often require significant water use. By adopting closed-loop systems, water usage is reduced, and contamination is minimized.

Additionally, manufacturers ensure that any wastewater or emissions meet regulatory standards before release, preventing harmful pollutants from entering local ecosystems. This attention to environmental compliance not only supports sustainability but also enhances the manufacturer’s reputation and credibility.

Eco-Friendly Product Design

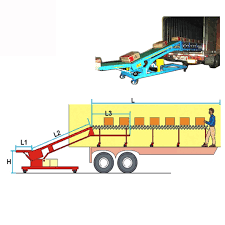

Sustainability is not limited to the manufacturing process; it also extends to the design of the conveyors themselves. Manufacturers are increasingly focusing on energy-efficient, lightweight, and modular designs that reduce operational energy consumption.

For example, conveyors with low-friction rollers or energy-saving motors require less electricity during operation, lowering the warehouse’s overall carbon footprint. Modular designs also allow for easy upgrades or repairs, extending the lifespan of the conveyor and reducing waste associated with replacement.

Certifications and Industry Standards

Adherence to environmental certifications and industry standards is a hallmark of sustainable truck loading conveyor manufacturing. Certifications such as ISO 14001 for environmental management and compliance with energy efficiency standards indicate that a manufacturer is committed to reducing environmental impact throughout the product lifecycle.

Compliance with these standards ensures that sustainable practices are integrated into every stage of production, from raw material sourcing to final assembly and distribution.

Economic and Social Benefits of Sustainability

Adopting sustainable manufacturing practices provides tangible benefits beyond environmental impact. Energy efficiency, waste reduction, and resource conservation translate into cost savings for manufacturers, which can be passed on to customers. Additionally, eco-friendly practices contribute to social responsibility, enhancing brand image and attracting businesses seeking to partner with environmentally conscious suppliers.

Sustainable practices also create safer work environments, as they often involve cleaner production methods and reduced exposure to hazardous materials for factory personnel.

Conclusion

Sustainable manufacturing practices among truck loading conveyor manufacturers are transforming the material handling industry. Through the use of recycled materials, energy-efficient production processes, waste reduction programs, eco-friendly designs, and adherence to environmental standards, these manufacturers are minimizing their environmental footprint while delivering high-quality products. By choosing manufacturers committed to sustainability, warehouses and distribution centers can not only improve operational efficiency but also contribute to a greener, more responsible supply chain. Investing in sustainably produced conveyors is a strategic step toward aligning operational excellence with environmental stewardship.