Press machines are critical in metalworking and manufacturing industries, performing essential tasks such as punching, bending, forming, and cutting metal sheets. The quality, durability, and efficiency of these machines depend heavily on the manufacturing techniques used by the producers. Advanced techniques ensure precision, safety, and long-term reliability, allowing industries to maintain consistent productivity and minimize operational downtime. Understanding the methods employed by press machine manufacturers provides insight into how these machines meet the high standards required in industrial applications.

A skilled Press Machine Manufacturer employs a variety of advanced manufacturing techniques that combine engineering expertise, precision machining, and stringent quality control. From component fabrication to assembly and final testing, these methods ensure that every press machine operates efficiently and safely. Modern manufacturers integrate innovative production processes, automated systems, and strict compliance protocols to deliver machines capable of handling diverse applications while meeting international quality and safety standards.

Material Preparation and Selection

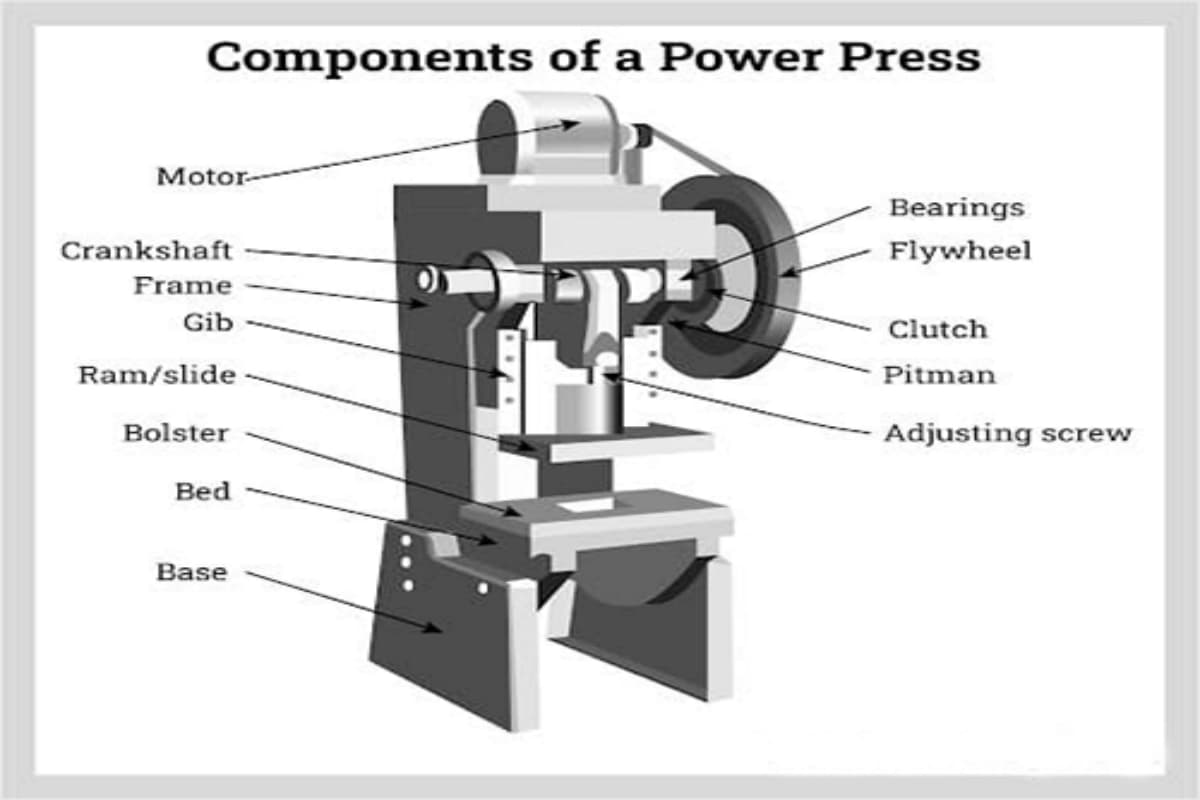

Manufacturing a high-quality press begins with careful material selection and preparation. Press machine manufacturers source premium materials such as high-strength steel, cast iron, and specialized alloys for critical components including frames, rams, flywheels, and guide mechanisms. These materials are chosen for their durability, fatigue resistance, and ability to withstand high operational forces. After selection, materials are cut, forged, or cast to approximate dimensions before entering precision machining processes. Material preparation ensures that the foundation of the press is strong and reliable.

Precision Machining

Precision machining is one of the most important techniques used by press machine manufacturers. CNC machines, lathes, and milling machines are employed to achieve tight tolerances and high dimensional accuracy. Critical components such as the ram, bed, flywheel, and die guides are carefully machined to ensure proper alignment and smooth operation. Precision machining minimizes friction and vibration, contributing to the longevity of the press and consistent performance during high-volume industrial operations.

Heat Treatment and Surface Finishing

Heat treatment is often applied to key components to improve hardness and resistance to wear. Processes such as quenching, tempering, or annealing enhance the strength of metal parts, allowing them to withstand repeated high-force cycles. Surface finishing techniques, including grinding, polishing, and coating, further protect components from corrosion and wear. By combining heat treatment and surface finishing, manufacturers ensure that press machines can maintain optimal performance over extended periods of use.

Assembly and Alignment Techniques

Proper assembly is crucial to the functionality and durability of press machines. Press machine manufacturers use specialized jigs and fixtures to ensure precise alignment of moving parts, including the ram, crankshaft, and guideways. Fasteners are tightened to exact torque specifications, and subassemblies are tested for smooth movement. Accurate assembly reduces operational stress on components and ensures that the machine maintains consistent performance and safety standards throughout its life.

Automation and Technological Integration

Modern manufacturing techniques increasingly involve automation. Robotic systems, automated material handling, and programmable assembly stations allow manufacturers to produce machines with higher consistency and lower error rates. Technological integration also extends to the press itself, with features such as PLC-based control systems, digital monitoring, and adjustable speed profiles. These advancements enhance operational efficiency, accuracy, and safety in the final product.

Quality Assurance and Testing

Quality assurance is a central part of the manufacturing process. Each press machine undergoes rigorous inspections and testing before leaving the factory. Load testing, stroke verification, alignment checks, and safety feature validation ensure that the press meets its specified performance and complies with international standards. Manufacturers document all inspection results to maintain traceability and support maintenance and service requirements over the machine’s operational life.

Customization and Specialized Techniques

Many manufacturers also offer customized press machines tailored to client-specific applications. This may involve specialized tonnage, stroke lengths, die compatibility, or integration with automated production lines. Customization requires flexible manufacturing techniques that can adapt to unique design requirements while maintaining precision and durability. Skilled manufacturers use advanced engineering, modular design principles, and adaptive machining processes to meet these specialized demands efficiently.

Conclusion

Press machine manufacturers employ a combination of advanced material preparation, precision machining, heat treatment, assembly techniques, automation, and rigorous quality assurance to produce reliable, durable, and high-performance machines. By integrating these manufacturing techniques, a reputable Press Machine Manufacturer can deliver machines that meet the rigorous demands of industrial applications while ensuring operational safety and efficiency. Understanding these techniques highlights the expertise, innovation, and quality standards that define professional press machine manufacturers, helping industries make informed decisions when selecting the right equipment for their production needs.