In modern logistics and warehouse operations, energy efficiency has become a critical factor for both environmental sustainability and operational cost management. With the increasing demand for high-speed loading and unloading, material-handling equipment consumes a significant amount of electricity. Telescopic conveyor systems, which are widely used for their flexibility and efficiency, can also contribute to high energy usage if not properly optimized. Understanding how to enhance energy efficiency in these systems helps businesses reduce operational costs while supporting greener practices.

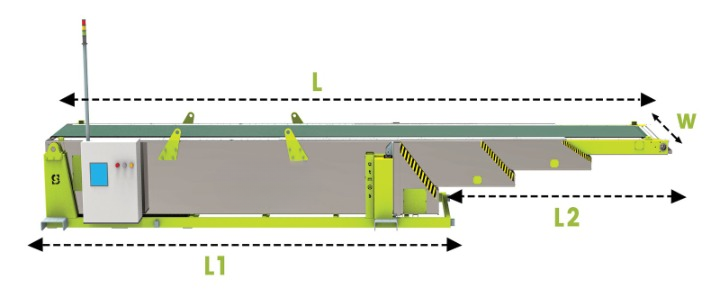

A telescopic conveyor is a system designed with extendable sections and motorized belts that move goods between warehouse floors and transport vehicles. While these systems improve loading efficiency, their energy consumption depends on multiple factors, including motor efficiency, conveyor length, load capacity, and operational patterns. Optimizing these aspects ensures that telescopic conveyors deliver high performance while minimizing energy waste.

Efficient Motor and Drive Systems

The heart of any telescopic conveyor system is its motor and drive mechanism. Modern conveyors often use electric motors to power both the belt and the extension/retraction mechanism. High-efficiency motors consume less electricity while providing consistent performance. Choosing motors with energy-saving features, such as variable frequency drives (VFDs), allows operators to adjust belt speed and power output according to operational demand. This prevents overuse of energy when the conveyor is lightly loaded or operating at lower speeds.

Regular maintenance of the motor and drive system also contributes to energy efficiency. Well-lubricated bearings, correctly tensioned belts, and properly aligned rollers reduce friction and energy loss. Neglecting these components can result in increased power consumption and higher operating costs over time.

Optimizing Conveyor Length and Extension

One key factor affecting energy consumption in telescopic conveyors is the length of the system in use. Extending the conveyor beyond necessary limits increases motor load and electricity usage. Operators should be trained to extend the conveyor only as far as required to reach trucks, containers, or pallets. Retracting the system when not in use reduces the energy needed to move both the telescopic sections and the belt.

Modern telescopic conveyors with automated extension and retraction controls can optimize energy usage by adjusting movement speed based on operational requirements. Sensors and smart control systems prevent unnecessary motor operation, further reducing energy waste.

Load Management and Distribution

Energy efficiency is closely tied to how the conveyor is loaded. Overloading the belt or unevenly distributing packages increases strain on motors and drives, leading to higher energy consumption. Maintaining balanced loads allows the system to operate smoothly without requiring excessive power to move the belt.

Additionally, implementing weight sensors and automated sorting systems can help manage load distribution dynamically. By regulating the load according to conveyor capacity and operational speed, facilities can prevent energy spikes and maintain consistent efficiency.

Belt Material and Friction Reduction

The type of conveyor belt used also affects energy efficiency. Belts made of low-friction materials reduce resistance between the belt and rollers, decreasing the power needed to move goods. Smooth, well-maintained belts help the motor operate at optimal efficiency. Facilities should periodically inspect belts for wear, misalignment, or damage, as worn belts increase friction and force motors to consume more energy to maintain performance.

Using modular or segmented belts designed for low resistance can further enhance efficiency, especially in high-volume operations where the conveyor operates continuously throughout the day.

Automation and Smart Controls

Integrating automation and smart control features can significantly improve energy efficiency in telescopic conveyor systems. Programmable logic controllers (PLCs), sensors, and automated start-stop mechanisms reduce unnecessary conveyor operation. For example, the system can remain idle when no packages are present or adjust motor speed based on real-time load data.

Advanced control systems also allow predictive maintenance alerts, ensuring that motors and mechanical components remain in optimal condition. Preventive maintenance reduces energy loss caused by worn bearings, misaligned rollers, or underperforming motors.

Reducing Idle Time and Operational Inefficiencies

Another method to improve energy efficiency is minimizing idle time. Conveyor belts that run continuously without moving goods consume electricity unnecessarily. Implementing start-stop schedules or automated triggers ensures the conveyor operates only when needed. This not only reduces energy consumption but also extends the lifespan of the motor and belt.

Operational inefficiencies, such as unnecessary conveyor extensions or excessive loading and unloading cycles, should also be addressed. Streamlining workflow patterns ensures the telescopic conveyor operates efficiently, conserving energy while maintaining throughput.

Environmental and Cost Benefits

Enhancing energy efficiency in telescopic conveyor systems has both environmental and financial benefits. Reduced electricity consumption lowers operational costs and decreases the carbon footprint of warehouse or logistics operations. Facilities that prioritize energy-efficient systems contribute to sustainability goals and may qualify for energy incentives or certifications, adding value to the business.

Conclusion

Energy efficiency in telescopic conveyor systems is a combination of smart design, proper operation, and preventive maintenance. Optimizing motor performance, controlling conveyor length and speed, managing loads, and integrating automation are key strategies for reducing energy consumption. By focusing on these practices, facilities can achieve lower operating costs, improved equipment longevity, and a more sustainable logistics operation. Energy-efficient telescopic conveyors not only support high-volume material handling but also promote environmentally responsible practices in modern warehouse and distribution centers.