Filtration is a critical process across chemical, pharmaceutical, food, and specialty manufacturing industries. Selecting the right filtration system can significantly impact product quality, production efficiency, and operational safety. Conventional filtration systems, such as plate and frame filters, candle filters, or rotary drum filters, have been used for decades to separate solids from liquids. However, modern production demands have driven the adoption of more advanced solutions like Agitated Nutsche Filters (ANFs), which combine filtration, washing, and drying in a single, enclosed vessel. Comparing these two approaches highlights the benefits and limitations of each, guiding manufacturers in choosing the most suitable technology for their operations.

A key advantage of an Agitated Nutsche Filter is its integrated design. Unlike conventional systems that often require multiple pieces of equipment to complete filtration, washing, and drying, ANFs perform all these processes in one enclosed vessel. The agitator ensures uniform solid distribution, prevents cake compaction, and facilitates effective washing and drying. This not only improves filtration efficiency but also reduces material handling, minimizes contamination risks, and shortens production cycles. In contrast, conventional systems typically require manual transfer of solids between separate units, increasing labor requirements, potential product loss, and safety hazards.

Filtration Efficiency

Filtration efficiency is one of the primary differentiators between ANFs and traditional systems. In conventional filters, uneven cake formation, channeling, and clogging can slow liquid flow and reduce overall separation performance. Agitated Nutsche Filters overcome these issues through continuous agitation during filtration, which promotes uniform cake thickness and prevents high-resistance zones. This results in faster filtration rates, higher throughput, and more consistent product quality. Conventional systems often require multiple filtration cycles or additional filter media to achieve similar levels of clarity, making ANFs more efficient in handling viscous slurries, fine powders, and complex materials.

Washing and Purification

Washing the solid cake to remove impurities, residual solvents, or reactants is critical in many industries, particularly pharmaceuticals and fine chemicals. ANFs provide superior washing capabilities compared to conventional filters due to the agitator, which distributes wash liquid evenly through the cake. This ensures thorough removal of contaminants and reduces the amount of solvent required. Conventional systems, such as plate and frame filters, often rely on static cake washing, which can leave unevenly treated regions and necessitate additional cycles to achieve desired purity. The integrated washing feature of ANFs not only improves product quality but also reduces process time and resource consumption.

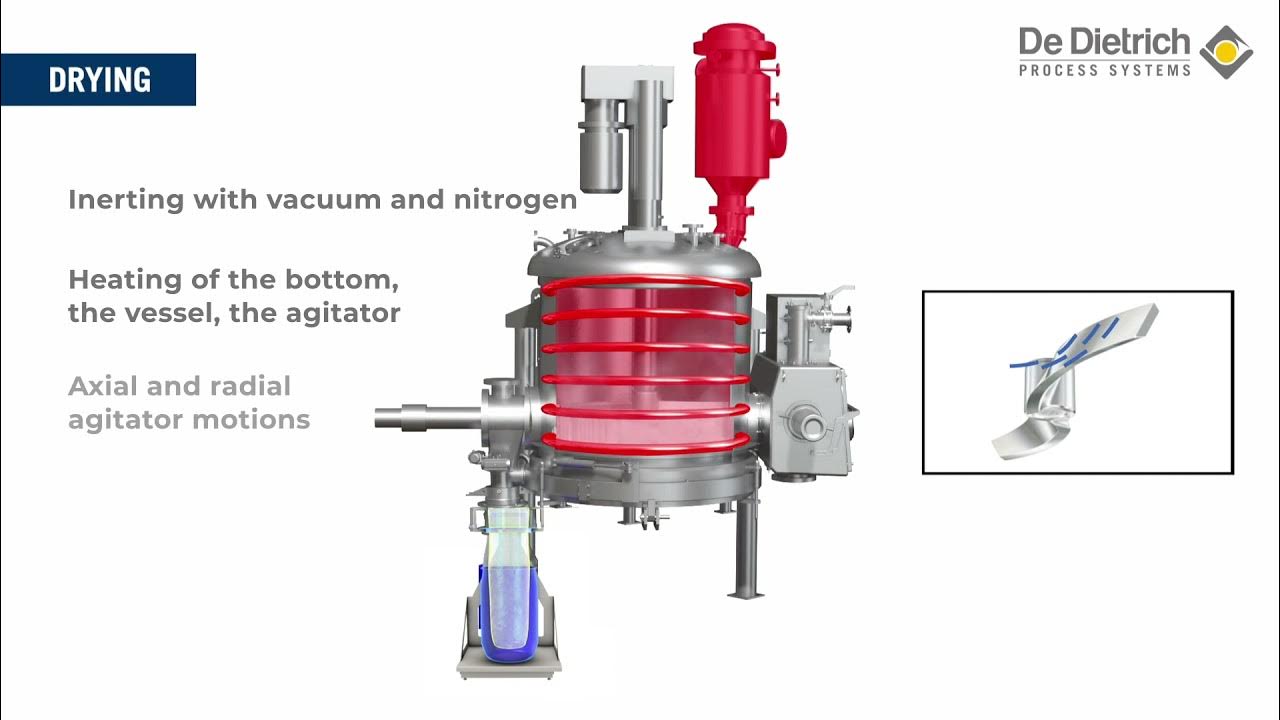

Drying Capability

Drying is another area where ANFs excel. The jacketed vessel allows precise temperature control using steam or thermal oil, and the agitator ensures uniform heat distribution throughout the solid cake. This enables efficient moisture removal without localized overheating or degradation of sensitive materials. Conventional filtration systems typically lack built-in drying capabilities, requiring separate drying equipment such as rotary dryers or fluidized bed dryers. The need to transfer solids between multiple units increases handling risk, processing time, and potential contamination. ANFs, by combining filtration, washing, and drying, streamline the process and enhance operational safety.

Safety and Containment

Safety is a major advantage of Agitated Nutsche Filters. Their closed-system design reduces operator exposure to toxic, flammable, or pyrophoric materials. Pressure and vacuum controls, along with mechanical seals and interlocks, provide additional protection. Conventional systems are often open or semi-enclosed, increasing the risk of spills, exposure to hazardous substances, and contamination of the work environment. For industries with strict regulatory requirements, such as pharmaceuticals, ANFs offer a safer and more compliant solution.

Automation and Process Control

Modern ANFs often feature automated controls for agitation, vacuum, pressure, temperature, and washing cycles. Real-time monitoring and process data logging allow operators to maintain consistent product quality and respond to abnormalities quickly. Conventional filtration systems generally require manual operation, which can introduce variability, increase labor costs, and make process optimization more challenging. Automation in ANFs ensures reproducibility, regulatory compliance, and reduced operational errors.

Versatility and Adaptability

Agitated Nutsche Filters are highly adaptable, capable of handling a wide range of materials, from viscous slurries to fine powders and abrasive solids. Modular designs, customizable filter media, and scalable vessel sizes allow manufacturers to optimize the system for specific processes. Conventional filters are often less flexible and may require separate units or extensive modifications to handle different products or batch sizes.

In conclusion, while conventional filtration systems remain suitable for basic separation tasks, Agitated Nutsche Filters offer significant advantages in efficiency, washing and drying integration, safety, automation, and versatility. By performing multiple steps within a single enclosed vessel, ANFs reduce handling, improve product quality, and streamline production processes. For industries that demand high purity, consistent throughput, and enhanced safety, Agitated Nutsche Filters represent a modern, superior solution to conventional filtration methods.